From an early age I was only ever happy making things, but as a War baby, money and materials were scarce, so brown paper, sticky tape, and corn flake boxes were the order of the day. Looking back, my first lucky break was to be able to join the Salvation Army Young People’s band. I never knew what the notes were called, but I learnt which valves to press down. Another life changing experience was being able to go to the pictures, for two of the local cinemas had organs. While the other kids whistled and booed, I would move to the front and be totally fascinated by the organist’s dexterity. Just what did all those knobs do? One day I would not only know, but also be able to play a similar instrument myself.

As a young school kid my only skill seemed to be that I was ‘good with scissors’. l now realise that I was the classic case of Dyslexia - which in those days just meant getting the cane a lot! At thirteen I made a crystal set, and life started to get a whole lot better. My first job as an apprentice radio engineer started me off on the electronics field that would keep me employed for the next 40 years. I was never able to work out all the formulas, but I seemed to have a gut feel for things, and earned a reputation for making things work. My lack of academic ability was a problem in getting qualifications, but - for example - when I needed to learn how TVs worked, my college tutor gave me an old 9 inch cathode ray tube, and I used it make my first TV. Not many other 17 year olds had a 9 inch device to tempt girls into their bedrooms!

Unfortunately, however, I never really got on too well with girls. They just didn’t seem to understand things like resistors and tuning capacitors. Despite this, at 19 I did meet a girl who showed great interest in my latest project - a 4 inch astronomical telescope. Julia was her name, and we have now been married for 46 years. By the way - the next telescope was a 6 incher (amazing what married life can do for a man!)

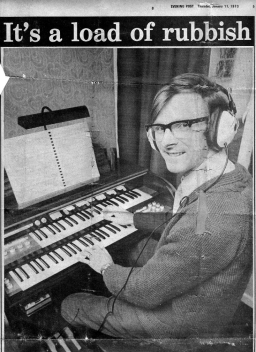

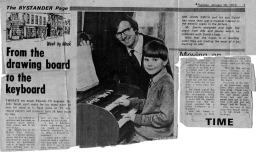

The adjacent picture shows Julia with the Original Busker, and me with the first Senior 20